Quality control is not only tightness.

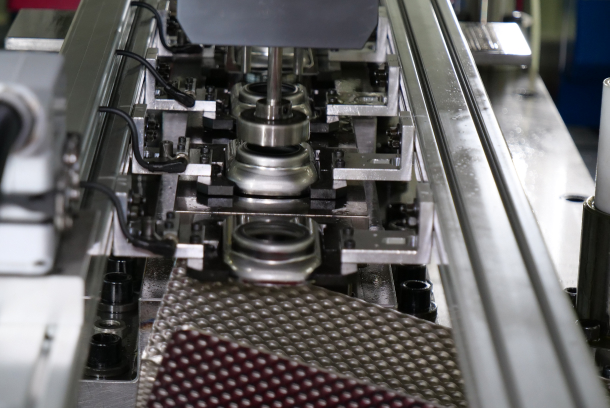

All TUBOG radiators undergo quality control for more than 60 parameters during the production process:

- metal control

- geometry control

- control of welding processes

- coating adhesion control

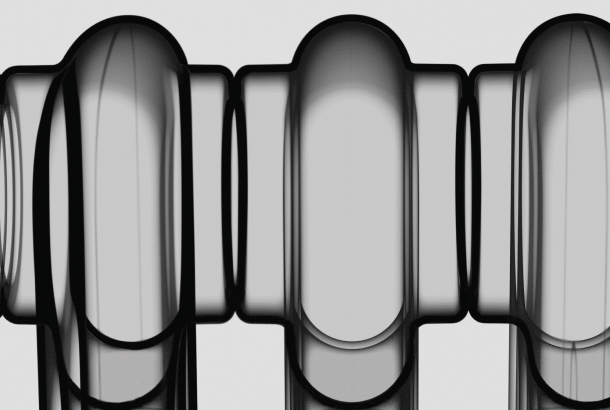

In particular, the use of the X-ray method of research in the technology of welding processes in production makes it possible to guarantee 100% control of welds.

Traditionally, X-ray control was performed on parts of the nuclear or aerospace industry, mechanical engineering objects mainly for military purposes and critical parts of various engines of both the aviation and automotive sectors of the industry.

The application of automated X-ray inspection technology for the production of heating radiators is a consequence of new technological advances in this industry. Such control has several key advantages over other methods — it reliability, speed and visibility.

Inspection of welded joints with automatic search for defects — a technology that is currently used in the production of TUBOG heating radiators.