Tubular radiators of the RIFAR TUBOG brand are manufactured at one of the most modern production facilities, launched in 2022. Based on many years of experience in the operation of heating devices in the Russian Federation, the following basic requirements are laid down in the design of RIFAR TUBOG tubular radiators:

- refusal use of intersectional joints with use of nipples and sealing elements;

- the use of only modern technologies of cold stamping and welding, ensuring the absence of external and internal defects in the area of welds;

- use of technical solutions that make it possible to connect tubular radiators with bottom connection to heat network without additional balancing valves to exclude coolant pulsations.

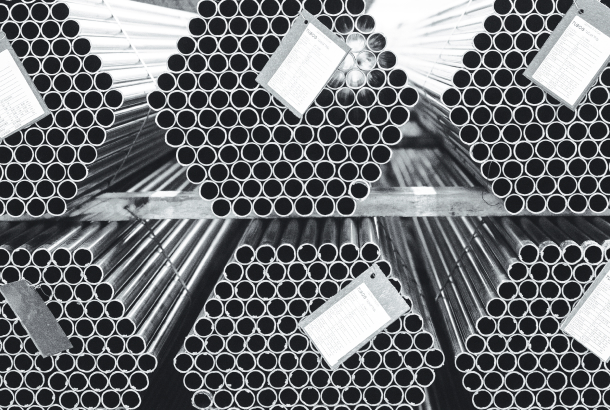

The presence of a modern scientific and laboratory complex, time-tested suppliers of materials and own production of pipes provide 100% quality control of all materials used in production.

For the manufacture of RIFAR TUBOG tubular radiators, only CORREX steel is used, which is characterized by a particularly high resistance to pitting corrosion. The steel thickness is 1.6mm, which is two times higher than the requirements for steel thickness for such radiators according to European standard EN442–1.

When manufacturing TUBOG radiators, the most environmentally friendly and advanced welding methods — laser and pulse contact. This allows you to create clean and high-quality seams without slag and welding beads.